Basic Info.

Model NO.

SF 1.499 UC Lens

Diameter

70mm

Transmission

> 97%

Guarantee

3~5 Years

Key Word

Sf Cr 39 1.499 UC

Brand

Seesen

Product Description

SEMI-FINISHED 1.499 SINGLE VISION

SEMI-FINISHED 1.499 SINGLE VISION | Blank Size | Normal Base | Back | C/T(mm) | E/T(mm) | Rad | Sag |

| (mm) | Curve | Curve(D) | ||||

| 70mm | 0.50C | 6.75 | 7.4 | 14.00 | 901.724 | 0.220 |

| 70mm | 1.00C | 6.75 | 7.2 | 13.40 | 523.000 | 0.380 |

| 70mm | 2.00C | 6.75 | 7.0 | 11.80 | 261.500 | 0.770 |

| 70mm | 4.00C | 5.60 | 10.5 | 10.96 | 142.119 | 1.410 |

| 70mm | 6.00C | 5.60 | 8.0 | 6.97 | 89.708 | 2.260 |

| 70mm | 8.00C | 6.75 | 8.2 | 6.20 | 64.727 | 3.165 |

| 70mm | 10.00C | 6.75 | 11.0 | 5.60 | 54.309 | 3.810 |

What is Semi-finished lens ?

Semi-finished lens is the raw blank used to produce the most individualized RX lens according to thepatient's prescription. Different prescription powers request for different semi-finished lens types or base curves.

The semi-finished lenses are produced in a casting process. Here, liquid monomers are first poured into moulds. Various substances are added to the monomers, e.g. initiators and UV absorbers. The initiator triggers a chemical reaction that leads to hardening or "curing" of the lens, while the UV absorber increases the UV absorption of the lenses and prevents yellowing.

The Advantages of 1.499 CR39 Lens

Hardness: The best among other index lenses in hardness and toughness, high impact resistance.

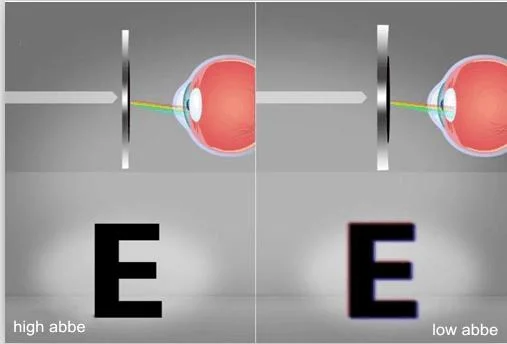

ABBE: The highest ABBE value providing the most comfortable visual experience.

Consistency: The most reliable and consistent lens product physically and optically.

Hardness: The best among other index lenses in hardness and toughness, high impact resistance.

ABBE: The highest ABBE value providing the most comfortable visual experience.

Consistency: The most reliable and consistent lens product physically and optically.

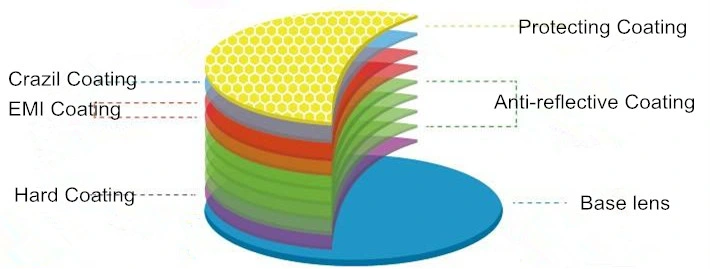

Coating Choice

Hard Coating(HC): To enhance the hardness of the lens to prevent the substrate scratch

Anti-reflection Coating(HMC/ AR): To protect the lens effectively from reflection, enhancing functional and charity of your vision

1. Are your company a manufacturer or a trade company?

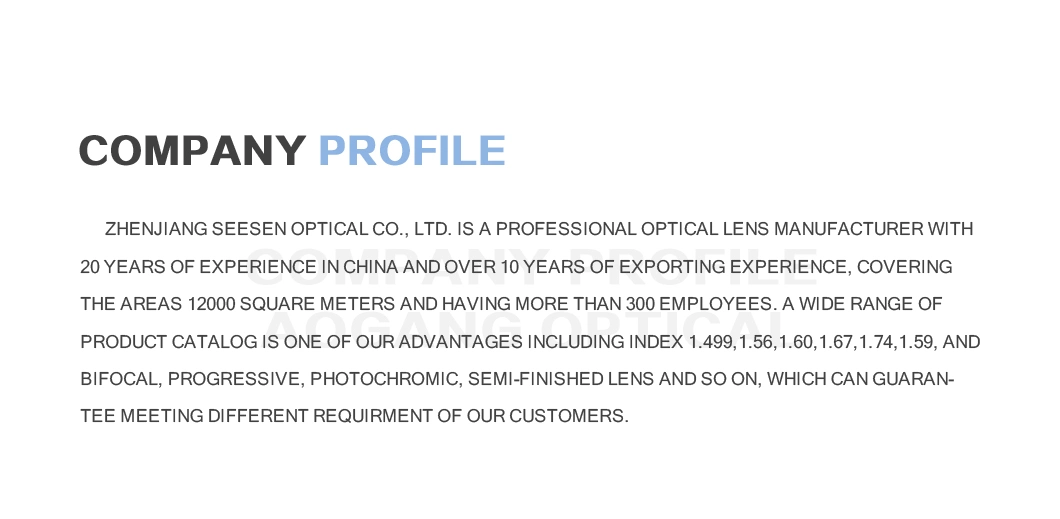

1. Are your company a manufacturer or a trade company?We are a manufacturer with many years exporting experience. Our factory is located in Jiangsu province.

2. Can your products be customized?

We accept OEM &ODM orders. Actually most of our products are customized. We will try our best to fulfill your requirements about the material, the size, the printing.

3. How can I get sample from you?

Just send us your requirements, then we will send samples accordingly.

4. How many days will samples be finished? How about mass products?

Generally, we need 5-7 days to finish the sample production.As for the mass products, it depends on your order quantity.

5. How do you control lens quality?

Producing process is in vacuum dust-free shop, like prepare material, mixed material and take out .Four times quality checking during production process.