Basic Info.

Model NO.

1.61 spin photochromic HMC

Diamater

65/70/75mm

Keywords

1.61 Spin Photochromic Hmc

Product Description

Free Service:

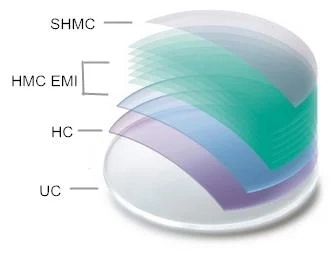

What are the photochromic lens?

Photochromic lenses are made of many lens materials including plastic, glass or polycarbonate. They are typically used as sunglasses that conveniently switch from a clear lens indoors, to a sunglasses depth tint when outdoors, and vice versa.

1.61 photochromic lens

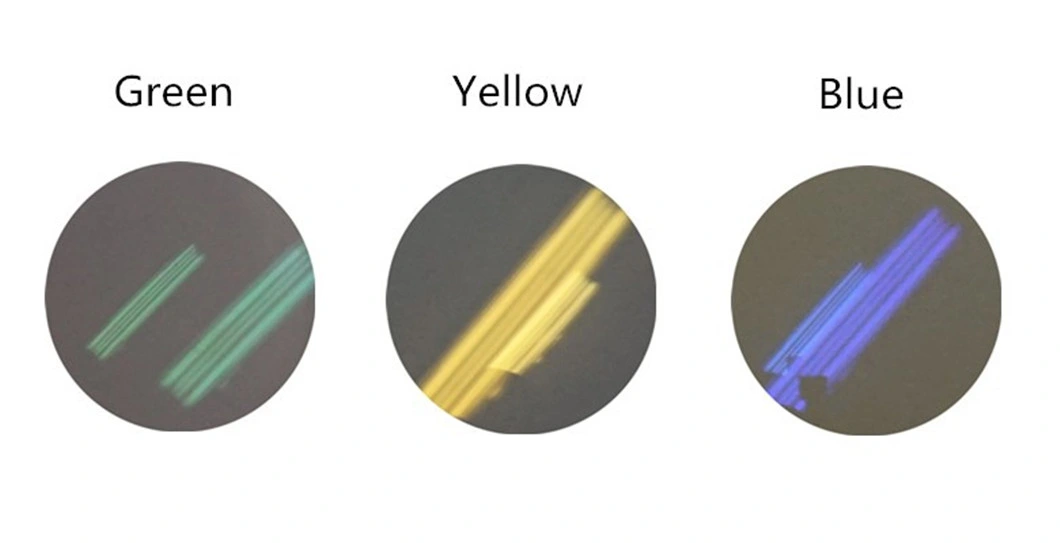

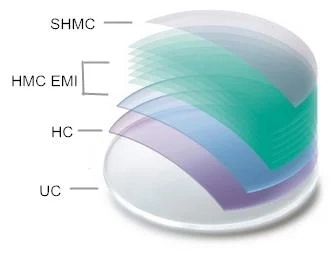

About the Coating

Depending on the layers of coating, lenses differ in functionality. Coating consists of much technicality as much as lenses do, here is ' how lens coating works ' for your reference.

Depending on the layers of coating, lenses differ in functionality. Coating consists of much technicality as much as lenses do, here is ' how lens coating works ' for your reference.

Comparison of physical properties of lenses

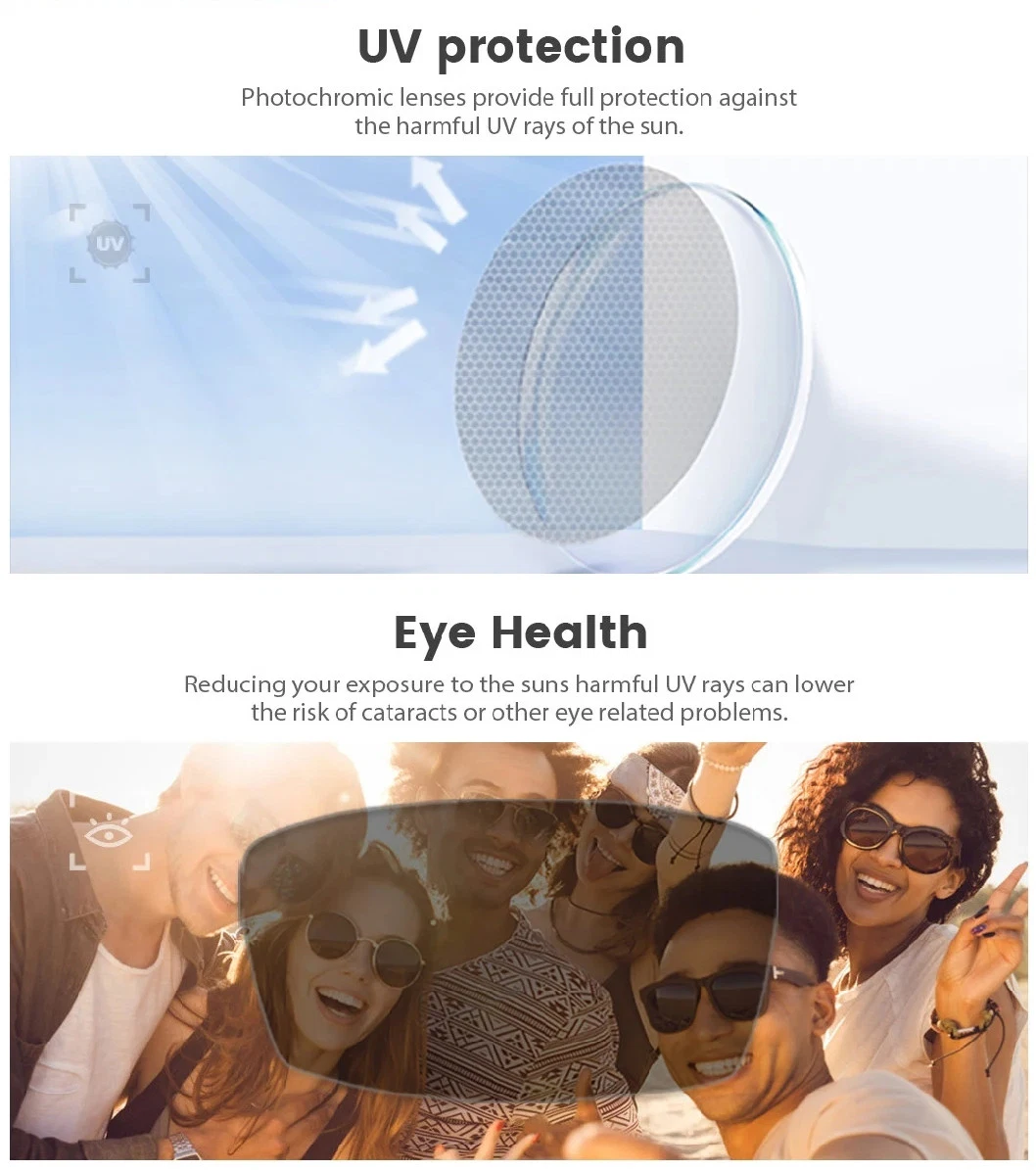

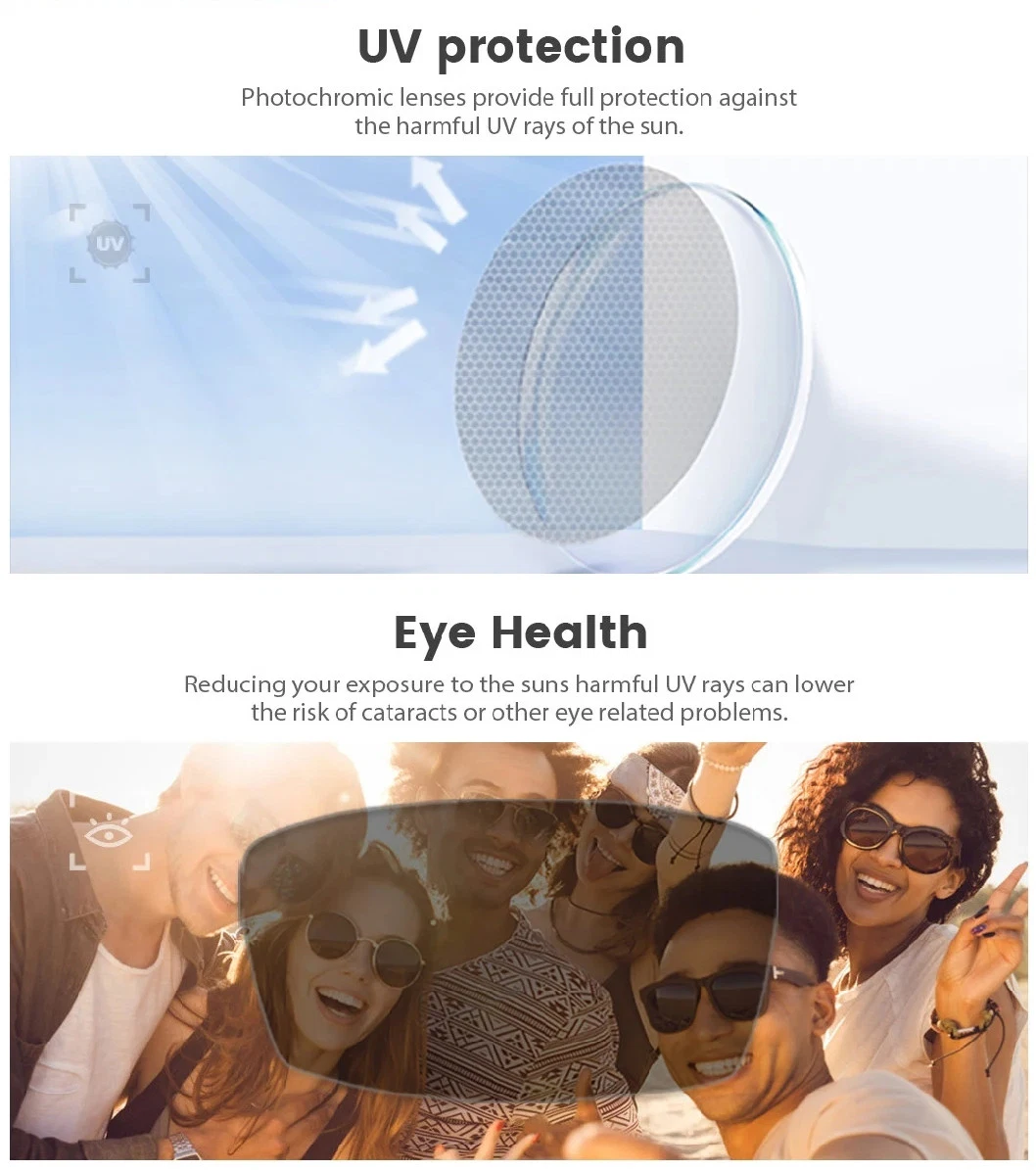

Advantages of the photochromic lens

Reduced costs - buying a single pair of dual purpose photochromic glasses that can provide vision for both indoors when clear and providing sunglasses protection outside is more cost effective than buying two separate pairs.

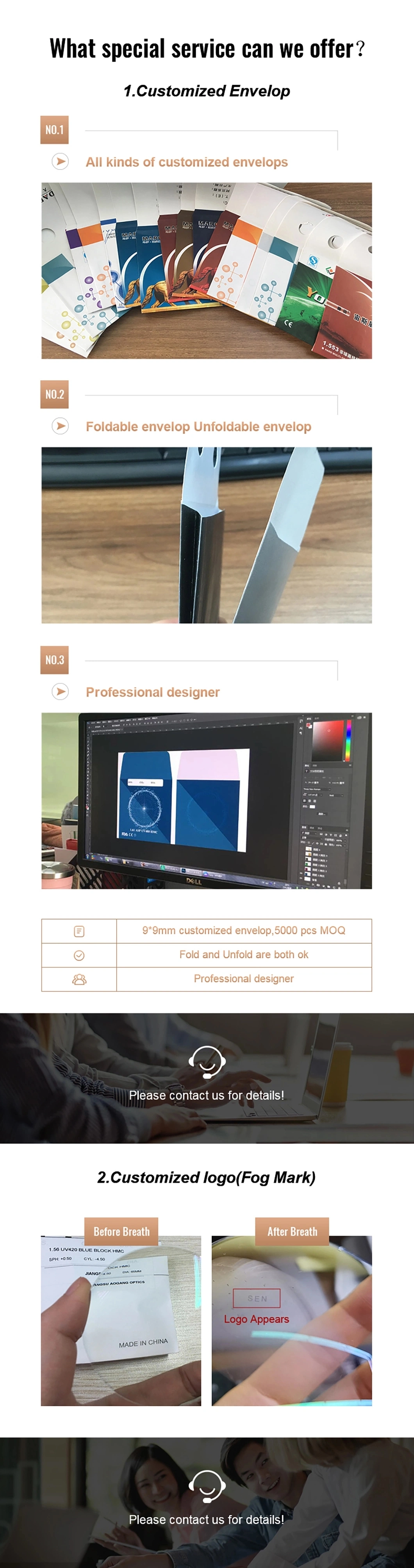

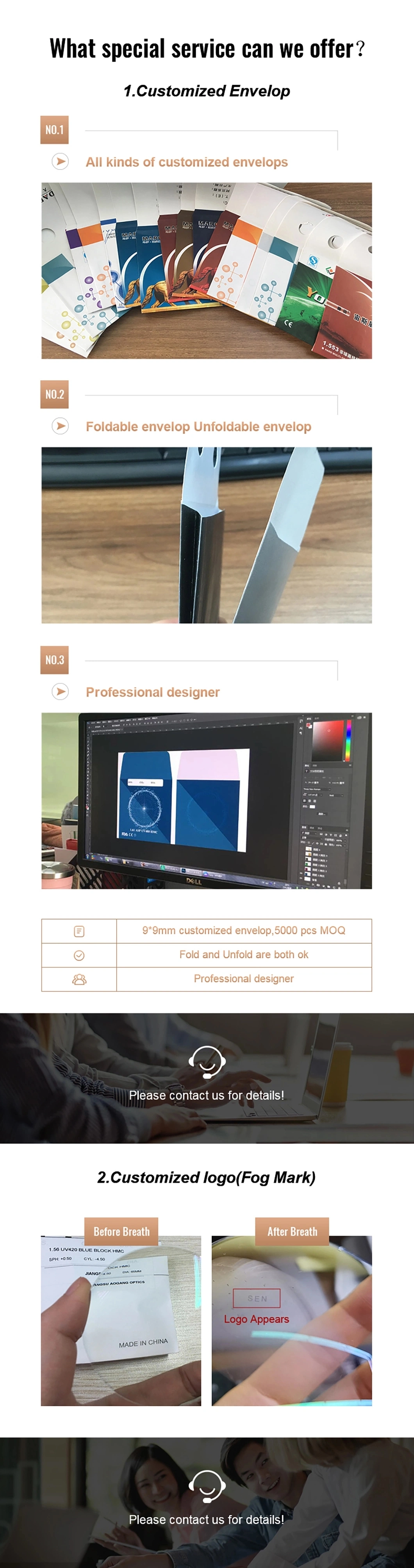

About the Custom Service:

About our Factory

FAQ:

1. Are your company a manufacturer or a trade company?

We are a manufacturer with many years exporting experience. Our factory is located in Jiangsu province.

2. Can your products be customized?

We accept OEM &ODM orders. Actually most of our products are customized. We will try our best to fulfill your requirements about the material, the size, the printing.

3. How can I get sample from you?

Just send us your requirements, then we will send samples accordingly.

4. How many days will samples be finished? How about mass products?

Generally, we need 5-7 days to finish the sample production.As for the mass products, it depends on your order quantity.

5. How do you control lens quality?

Producing process is in vacuum dust-free shop, like prepare material, mixed material and take out .Four times quality checking during production process.

What are the photochromic lens?

Photochromic lenses are made of many lens materials including plastic, glass or polycarbonate. They are typically used as sunglasses that conveniently switch from a clear lens indoors, to a sunglasses depth tint when outdoors, and vice versa.

1.61 photochromic lens

| Product Name | Diameter | Monomer |

| 1.61 Spin Photochromic HMC Eyeglasses Optical Lenses | 65/70/75MM | MR-8 (imported from Korea) |

| Abbe value | Specific Gravity | Power Range |

| 41 | 1.30 | SPH: 0.00~ -6.00, 0.00~ +6.00 CYL: 0.00~ -6.00 |

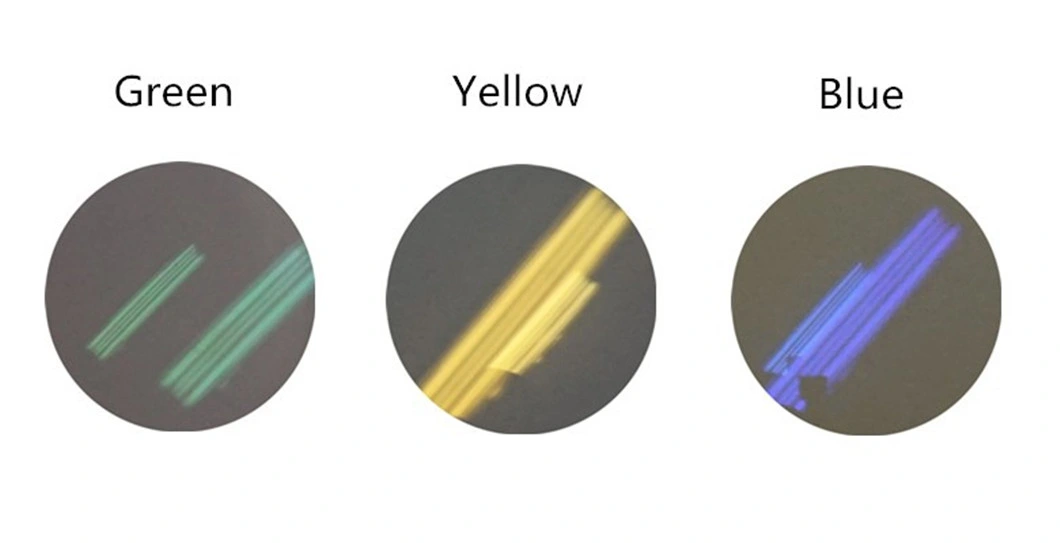

About the Coating

Depending on the layers of coating, lenses differ in functionality. Coating consists of much technicality as much as lenses do, here is ' how lens coating works ' for your reference.

Depending on the layers of coating, lenses differ in functionality. Coating consists of much technicality as much as lenses do, here is ' how lens coating works ' for your reference.

Hard Coating: To protect the uncoated lenses from scratch resistance.

AR Coating/Hard Multi Coating: To protect the lens effectively from reflection, enhance functional and charity of your vision

Super Hydrophobic Coating/Crazil Coating: To make the lens waterproof, antistatic , anti slip and oil resistance.

Comparison of physical properties of lenses

| MR-8 | MR-7 | MR-174 | Polycarbonate(PC) | NK-55 | CR39 | |

| Referactive Index | 1.61 | 1.67 | 1.74 | 1.59 | 1.56 | 1.49 |

| Abbe Value | 41 | 32 | 33 | 32 | 37.5 | 58 |

| Specific Gravity | 1.30 | 1.35 | 1.47 | 1.20 | 1.28 | 1.32 |

| Diameter | 65/70/75 | 65/70/75 | 65/70/75 | 65/70/75 | 55/60/65/72 | 55/60/65/70 |

| Impact Resistance | Good | Good | Good | Good | Good | Good |

| Static Load Resistance | Good | Good | Good | Good | Good | Good |

Advantages of the photochromic lens

Reduced costs - buying a single pair of dual purpose photochromic glasses that can provide vision for both indoors when clear and providing sunglasses protection outside is more cost effective than buying two separate pairs.

About the Custom Service:

About our Factory

FAQ:

1. Are your company a manufacturer or a trade company?

We are a manufacturer with many years exporting experience. Our factory is located in Jiangsu province.

2. Can your products be customized?

We accept OEM &ODM orders. Actually most of our products are customized. We will try our best to fulfill your requirements about the material, the size, the printing.

3. How can I get sample from you?

Just send us your requirements, then we will send samples accordingly.

4. How many days will samples be finished? How about mass products?

Generally, we need 5-7 days to finish the sample production.As for the mass products, it depends on your order quantity.

5. How do you control lens quality?

Producing process is in vacuum dust-free shop, like prepare material, mixed material and take out .Four times quality checking during production process.